Understanding vs. Quick Fixes

As technicians, we often find ourselves at a crossroads when a customer’s machine is down. The gears might be stripped, and the motor struggles to function, leading many to jump at the chance for an easy fix: replace the defective parts, get the machine running again, and quickly move on to the next job. But herein lies a critical mistake that many technicians make.

The Deep Understanding Difference

Having spent years as a technical escalation lead supporting over 300 technicians, one lesson was undeniably clear: quick fixes frequently result in repeat failures. For instance, consider a real scenario where a machine faced failing gears and a defective motor. The instinctive reaction might be to replace these parts, but just days later, the machine failed again. Why? The critical question wasn’t asked: what caused the parts to fail in the first place? The answer lay within the machine itself — a dropped wrench was causing intermittent damage. Without identifying that root cause, we could have endlessly replaced parts.

The Cost of Surface Solutions

Quick fixes can end up costing more than we realize. They may lead to:

- Repeated repairs

- Multiple service calls

- Frustrated customers

- Damaged reputation

- Loss of productivity

To break this cycle, it’s essential to embrace a deeper understanding of the machines we work on. Investigating root causes, not just symptoms, is paramount. Rushing through repairs may yield immediate results, but it neglects long-term reliability and customer satisfaction. As technicians, developing diagnostic intuition and connecting symptoms to their underlying causes is vital for building expertise and trust with our clients.

Ultimately, as we navigate through our technical journeys, let’s remember: fixing things quickly might seem appealing, but investing time in understanding will yield greater rewards, ensuring we don’t just put a bandage on the issue but truly resolve it.

Let me tell you a story that every technician should hear. Picture this: A customer’s machine is down. The gears are stripped, the motor’s struggling. The easy fix? Replace the parts, get it running, move on to the next job. But here’s where most technicians go wrong.

The Deep Understanding Difference

I spent years as a technical escalation lead, supporting over 300 technicians. One lesson stood out: Quick fixes often lead to repeat failures. Here’s a real example:

A machine had failing gears and a damaged motor. The obvious solution? Replace the parts. But three days later, everything failed again. Why? Because nobody asked the crucial question: What caused those parts to fail in the first place?

The answer was hiding in the rack – literally. A dropped wrench, forgotten and “unimportant” according to the customer, was causing intermittent damage. Without finding that root cause, we could have replaced parts indefinitely.

Here’s what I learned from 20+ years in electronics engineering

This approach isn’t just about fixing machines – it’s about building expertise. When you truly understand systems, you can:

- Diagnose problems faster

- Prevent future failures

- Build customer trust

- Reduce overall costs

- Improve system reliability

- Builds Confidence

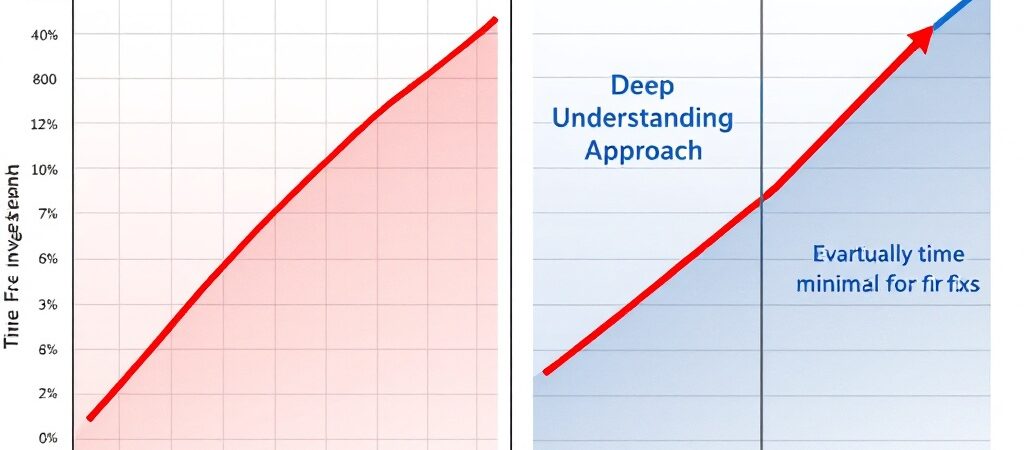

The Investment That Pays Off

Yes, this approach takes more time initially. I used to stay hours after finding the immediate fix, just to understand why something failed. Some thought this was excessive. But here’s the truth: That investment paid off exponentially. Eventually, I could diagnose issues before opening machines, saving countless hours and resources.

Conclusion

In our rush to fix things quickly, we often miss the opportunity to fix them permanently. True expertise isn’t about knowing which parts to replace – it’s about understanding why they failed in the first place. It’s the difference between being a parts-replacer and becoming a true technical expert.

Remember: The next time you’re tempted to just “fix it and go,” ask yourself – what might you be missing? That extra time spent understanding could save hours of future repairs. Every time you find the real issue you become that much better!

By Dr. Al Gorithm (William Mastrocola)

Disclosure: Dr. Al Gorithm here! 🤓 Just want to let you know that as an Amazon Associate, Lucrum Links earns from qualifying purchases. This means if you click on our links and buy something, we get a small commission (at no extra cost to you). We only recommend products we genuinely believe in – because that’s how we roll!

This helps keep our tech-loving operation running and lets us continue bringing you honest, detailed reviews. Thanks for supporting our mission to demystify the world of tech!